Högpresterande materials mekaniska egenskaper

Our firm belief is that long life-time of products is guaranteed by defect free manufacturing and advanced microstructure control in the production. One of the most important parameters for advanced steels are their mechanical properties in terms of wear resistance at different temperature, fatigue properties, tensile and fracture toughness. In this project we investigate the relation between the mechanical properties and the microstructure, and uses initiation points for failure to detect critical microstructural defects.

Advanced materials for high performance products – AMHiPP

Industrial drivers for development of materials with higher strength are several, e.g. reduction of tooling costs per produced component and increasing performance of the final product. Increasing material performance pushes development in upstream processes such as powder metallurgy (PM) and additive manufacturing (AM). Target applications are such as high performance tools, near-net shaped components, aerospace components, compressor valve components, surface engineered components, press hardening and die casting tools, and advanced cutting tools.

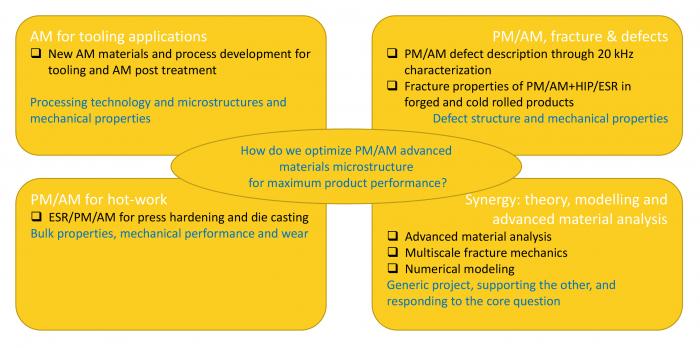

Together with the industrial partners (Uddeholm AB, Curtiss-Wright Surface Technologies AB, FTB Bredaryd AB, GKN Aerospace AB, Gestamp Hardtech AB, SECO Tools AB, Voestalpine Precision Strip AB, and Sandvik Powder Solution AB we formulated the research question: “How do we optimize PM/AM advanced materials microstructure for maximum product performance?”

The project is funded by the Knowledge Foundation (KK-stiftelsen) and runs over three years with a total turnover of 28 MSEK.

Contact persons at Karlstad University are:

Mikael Grehk, Professor, Project manager, mikael.grehk@kau.se, +46-(0)54-7002280

Jens Bergström, Professor, jens.bergstrom@kau.se, +46 (0)54 7001259

Pavel Krakhmalev, Professor, pavel.krakhmalev@kau.se, +46 (0)54 700 20 36

The research question is approached from different themes in four subprojects as is illustrated in the figure below: