WoodPro

Bio-based resources from well managed forests play important roles as material in transition to a sustainable society. In WoodPro, we explored possibilities of new processing chains for forest residues by avoiding the conventional incineration of the residues and replacing them with step-by-step processing to produce high-value industrial chemicals and soil amendments.

Project at a glance

Ali Mohammadi, associate professor in environmental and energy systems, is the leader of the Nordic Consortium that received Tandem Forest Values 3 grant from Research Council of Finland (Finlands Akademi) and Swedish Research Council Formas. The project WoodPro, explored possibilities of new processing chains for forest residues by avoiding the conventional incineration of the residues and replacing them with step-by-step processing to produce high-value industrial chemicals and soil amendments. WoodPro was jointly hosted by Karlstad University (KAU), Natural Resources Institute Finland (LUKE) and the University of Eastern Finland (UEF).

The WoodPro project scheme showing subprojects and participating institutions.

Project period

September 2022 - February 2025

WoodPro core team

- Ali Mohammadi (Karlstad University, Sweden)/ Consortium leader

- Narasinha Shurpali (Natural Resources Institute Finland)/Subproject leader

- Reijo Lappalainen (University of Eastern Finland)/ Subproject leader

Funding acknowledgement

This project was funded by Research Council of Finland (Finlands Akademi) and The Swedish Research Council for Environment, Agricultural Sciences and Spatial Planning- FORMAS under the call Tandem Forest Values 3 – Sustainable value chains from forest raw material.

Grant Number at Formas: 2022-01942

Project abstract

Bio-based resources from well-managed forests play a crucial role in the transition to a sustainable society. Given their limited supply and multiple utilization pathways, efficient use is essential to achieving bioeconomy and environmental goals. The WoodPro project explored innovative processing chains for forest residues, shifting from conventional incineration to stepwise processing for high-value industrial chemicals and soil amendments.

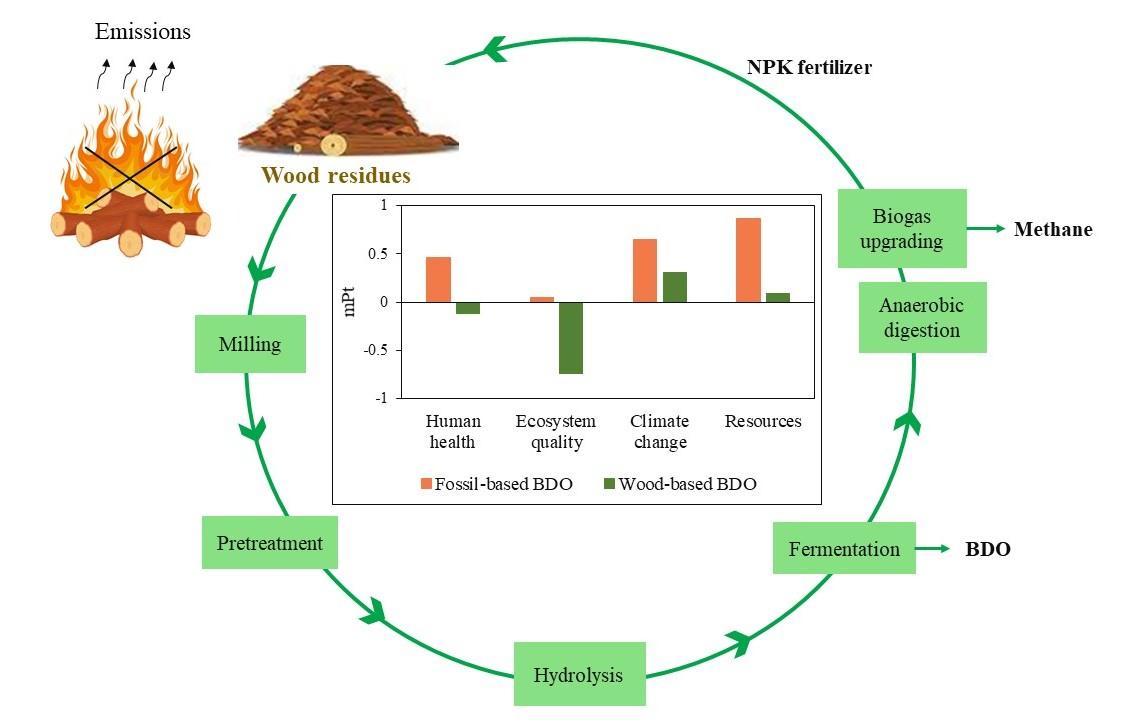

WoodPro identified the most sustainable biorefining alternatives for converting forest residues into 2,3-butanediol (BDO), biopolymer, and biochar products. Life cycle assessment (LCA) and techno-economic analysis (TEA) were employed to evaluate environmental and economic sustainability indicators. Results showed that avoiding wood combustion in favor of BDO production significantly outperforms fossil-based BDO across all environmental impact categories. Economic analysis found BDO production financially viable under three scenarios, with a minimum selling price of USD 2.9–3.5/kg, though process configuration and waste management strategies greatly influenced profitability.

Life cycle assessment of the joint production of BDO and biogas from wood residues.

For biochar, a growth experiment at Karlstad University demonstrated that seedlings with 7.5% biochar and 50% fertilizer, or 15% biochar and 100% fertilizer, achieved comparable quality to untreated seedlings with full fertilization. LCA results indicated that applying biochar without additional fertilizers offers substantial CO₂-equivalent savings of up to 300 kg annually at field scales. TEA revealed that advanced wastewater treatment in hydrothermal carbonization (HTC) incurs higher initial costs but delivers superior financial returns.

Biopolymer production (PHA) from residual streams was also investigated, but low accumulation rates hindered economic feasibility under the tested methodology.

Findings highlight that joint production of biochar and biogas presents the most sustainable scenario for wood residue treatments. Further research is recommended to optimize anaerobic digestion for waste management in BDO and biochar production, as well as to assess biochar’s impact on GHG emissions across different soil types.

The project findings contribute to the broader development of circular bioeconomy strategies and encourage the adoption of innovative and sustainable technologies in forest-based industries.

Publications

KAU

Peer-reviewed publications

- Ebrahimian, F., & Mohammadi, A. (2024). Bioprocess design and technoeconomic Analysis of 2, 3-butanediol production in wood-based biorefineries. Waste and Biomass Valorization, 15(12), 6635-6648.

- Ebrahimian, F., & Mohammadi, A. (2023). Assessing the environmental footprints and material flow of 2, 3-butanediol production in a wood-based biorefinery. Bioresource Technology, 387, 129642.

Conference presentations

- Mohammadi, A. (2024). Advancing sustainable biorefinery systems with innovative wood-based products. The 16th Southern African-Nordic Centre (SANORD) Annual Scientific Conference, Cape Town, South Africa, December 4-6, 2024.

- Mohammadi, A., Ebrahimian, F. (2024). Sustainable valorization of wood residues through biorefinery process: environmental and economic benefits. circular economy: the pathway towards a sustainable development of the hellenic society for circular economy, Chania, Greece, September 12-13, 2024.

- Mohammadi, A., Granström, K., & Ebrahimian, F. (2023). Biorefinery processes for value addition from forest residues: Sustainable and innovative scenarios. The 4th International Conference Bioresource Technology for Bioenergy, Bioproducts & Environmental Sustainability, Lake Garda, Italy, May 14-17, 2023.

- Ebrahimian, F., Mohammadi, A. (2023). Spruce wood biorefinery for integrated production of 2,3-butanediol and biogas: material and energy flow analysis. The 4th International Conference Bioresource Technology for Bioenergy, Bioproducts & Environmental Sustainability, Lake Garda, Italy, May 14-17, 2023. [Awarded as the best poster presentation]

LUKE & UEF

Peer-reviewed publications

- Bhattarai, H. R., Honkanen, E., Ruhanen, H., ... & Shurpali, N. J. (2025). Effects of biochar, hydrochar and nitrogen fertilization on greenhouse gas fluxes, soil organic carbon pools, and biomass yield of boreal legume grassland. Biochar, 7, 114.

- Shurpali, N., Li, Y., Tampio, E., Lappalainen, R., Mohammadi, A., Sandberg, M., ... & Granström, K. (2025). From fossil-based to circular bioeconomy: a Swedish and Finnish pathway. Environmental Science and Pollution Research, 32, 11308-11316.

- Xiang, Y., Mao, Y., Liu, Y., Luo, Y., Xue, J., He, J., ... & Li, Y. (2025). Enhancing Switchgrass Growth With Biochar Derived From Mushroom Residue: A Study on Regulating Physicochemical Properties of Acidic Phosphogypsum. Food and Energy Security, 14(1), e70034.

- Hazeena, S. H., Shurpali, N. J., Siljanen, H., Lappalainen, R., Anoop, P., Adarsh, V. P., ... & Binod, P. (2022). Bioprocess development of 2, 3-butanediol production using agro-industrial residues. Bioprocess and Biosystems Engineering, 45(9), 1527-1537.

Workshops and research visits

- Online workshop hosted by Karlstad University on March 24 2023 with over 20 industry repsentatives from Sweden and Finland. The event focused on collaborative discussion toward forming a roadmap for future forest-based bioeconomy.

- Research visit hosted by Karlstad University at KTH Royal Institute of Technology, Stockholm, Sweden for Finish research partners, December 4-5 2023.

- Research visit hosted by University of Eastern Finland In Kuopio, Finland for Swedish research partners, October 31-November 1 2024.